COOLING TOWER MOTORS

Three-Phase TEFC & TEAO Air Handling Motors WEG’s cooling tower motors are designed

for operation in 100% humidity and the most

corrosive environments. They designed

to operate in either horizontal or vertical

mounting.

WEG’s W22 cast iron platform has an

improved cooling system and solid feet for

cooler operation and reduced vibration and

noise extending the life of the motor.

Standard Features:

• 50/60 Hz rated (380V on Nameplate -

400/415 Available - Same Horse Power at

50 Hz with a 1.0 service factor)

• Class F insulation (Impregnation Resin and

magnet Wire are class H)

• Standard mounting is F2. F1 mounted

motors are identified in the part number.

(Both configurations are convertible).

Frames 447T and up can easily be

converted by simply rotating the terminal

box adapter

• Stainless Steel Nameplate - Laser etched

with high contrast background

• Double Sealed bearings

Features that make a difference:

• 1.25 service factor

• Multiple endbell drain plugs for

shaft up, down or horizontal

mounting

• Drain plugs in terminal box

• Rubber lead separator between

terminal box and frame

• Internally and externally epoxy

painted

• Double sealed bearings

• Double impregnation and bake

Cooling Tower - NEMA Premium Efficiency - Three Phase -TEFC/TEAO

WEG’S Cooling Tower - NEMA Premium Efficiency motors meet or exceed all EISA2007 requirements for energy efficiency.

These TEFC and TEAO motors are built according to NEMA standards and

designed for operation in 100% humidity and the most corrosive environments.

The entire line is Inverter Rated for use with Variable Frequency Drives. They are

designed to operate in either horizontal or vertical shaft up/down position. Sealed

bearing in all sizes require no lubrication.

As with any other WEG motor, Cooling Tower motors are tested in accordance with

IEEE 112, Method B, and their efficiency values are certified by UL (CSA C390).

Cooling Tower motors will meet Design B torques, maintaining exceedingly high breakdown and

locked rotor torque while providing the highest rated efficiency levels.

STANDARD FEATURES

• Three-phase, 1800, 1200, 1800/900 and 1200/900RPM 60Hz

• Voltage: 208-230/460V, 200V, 460V or 575V 60Hz

• 1.25 Service Factor at 60Hz for Single Speed motors

• 1.15 Service Factor at 60Hz for Two-Speed motors

• Single Speed available from 1-100Hp and also rated 380V 50Hz 1.0SF

• Available in Totally Enclosed Fan Cooled – TEFC – and Totally Enclosed Air Over–

TEAO – water/dust tight (IP55)

• Multiple End Shield Drain plugs for all mounting position

• Multiple Drain plugs on Terminal Box

• Rubber Lead Separator (isolator) between Terminal Box and Frame

• Joint Seal between frame and brackets

• Internal and External Epoxy Paint for increased corrosion protection

• V-ring slinger on both end shields

• Umbrella Seal on drive end prevents water tracking down shaft in shaft up installations

• Double Sealed Anti-Friction Ball Bearings - maintenance free

• NEMA frames 143T-445T

• Class ‘F’ insulation in all frames for increased reliability

• Class ‘H’ resin insulation system

• Class ‘B’ (80ºC) Temperature rise at full load for longer life

• Continuous duty (S1)

• NPT threaded, Cast Iron terminal box rotatable in 90º increments

• F2 mount (Standard Configuration); F1 available as stock mod

• Laser Etched AISI 316 Stainless steel nameplate

• MGI Part 31 rating for use with VFD - 1000:1 VT speed range

OPTIONAL FEATURES

• Thermostats

• Thermistors

• Space Heaters

• Shaft Grounding Device

• Drip covers for shaft down TEFC

WEG W22 Cooling Tower Duty Motors

CONDUIT BOX

Fully Gasketed, Cast

Iron conduit box

includes drainplugs,

lead separator gasket

and internal epoxy

coating

FRAME

Made of high grade FC-200 cast

iron for maximum cooling.

Includes additional grounding lug

and external epoxy paint

PERMANENTLY SEALED

and Lubricated bearing provide maintenance free long life

INTERNAL EPOXY COATING

Entire interior of the motor is

coated with epoxy for maximum moisture/corrosion resistance

DRAIN PLUGS

Located every 90 degrees and on the face of each endshield.

Easy to open and

accommodates all mounting configurations

All single-speed premium efficiency models meet NEMA®† premium efficiency levels

● Thousands of configurations to choose from

VBXX seals are installed on the "wet" end of the high-efficiency motor

The rotor balance of the high-efficiency motor is better than 0.08 inches/second

●Comply with IEC 34-5 grade IP55

Inverter duty cycle and two-speed models help customers meet ASHRAE standard 90.1

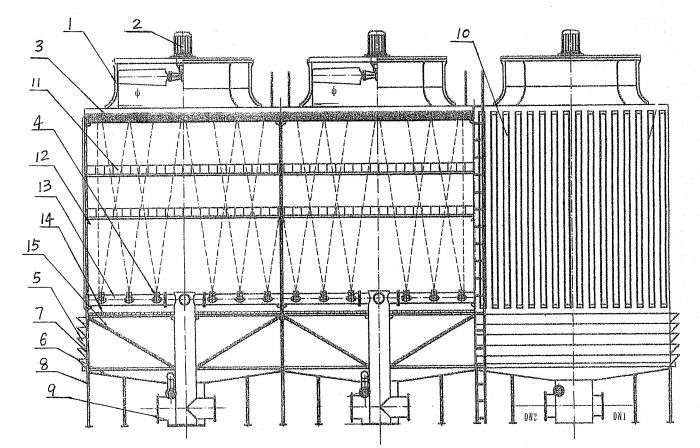

The motor is a new generation of cooling tower special three-phase asynchronous motor matched by our company. Its design concept and structure type are integrated into the new scientific research achievements of our company in the cooling tower motor industry over the years, and the use environment of the cooling tower motor is fully considered. In terms of sealing, moisture resistance, water resistance, reliability, etc., it is reasonably matched with the cooling tower, and fully meets the outdoor protection requirements for long-term operation in humid and hot environments. The product has reached the international advanced level and is a new type of cooling tower motor.

The motor adopts two installation types: IM V30 and IM V1:

IM V30 type: The machine base has no feet and is fixed by the direct-connected bracket, which is used for direct-connected fans.

IM V1 type: The machine base has no feet, the end cover has a flange, and it is equipped with a reducer.

The motor rating is a continuous rating based on the continuous duty system S1, and the protection level is IP54.

IM V1 type: The machine base has no feet, the end cover has a flange, and it is equipped with a reducer.

The motor rating is a continuous rating based on the continuous duty system S1, and the protection level is IP54.

IM V1 type: The machine base has no feet, the end cover has a flange, and it is equipped with a reducer.

The motor rating is a continuous rating based on the continuous duty system S1, and the protection level is IP54.

IM V1 type: The machine base has no feet, the end cover has a flange, and it is equipped with a reducer.

The motor rating is a continuous rating based on the continuous duty system S1, and the protection level is IP54.